Packaging, palletisation and distribution

Driving down our impact – our journey is reducing our carbon footprint.

Supporting the world around us

The display is just the beginning. This is as true of its impact on the planet as it is of our total solutions approach. The way we package our products and their journey from our factories to our customers are as important to their footprint as the components they are made from and our manufacturing processes.

Engagé à faire la différence pour les générations à venir

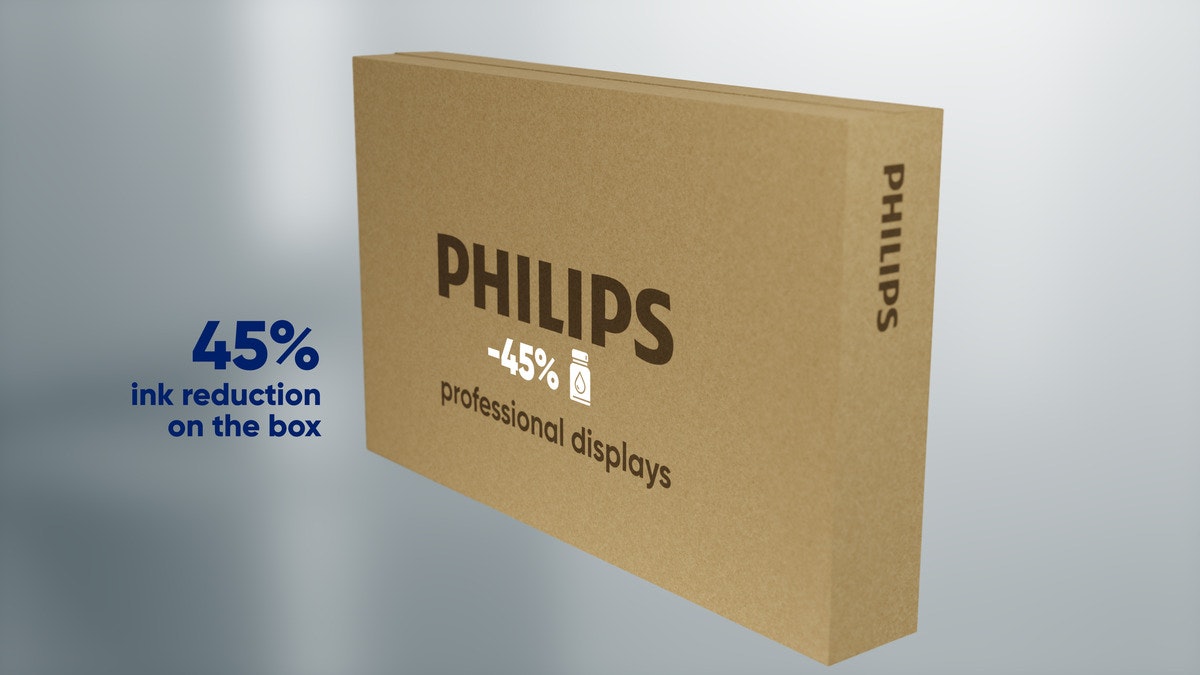

Packaging

Our packaging refinements are ongoing and our products are contained in reduced packaging, carefully calculated to minimise resources used and to maximise the number of products able to be loaded in any one shipment. This ethos is continued through the packaging of our pre-production components, with finished products almost fully made of recyclable materials.

This helps to reduce our carbon footprint without compromising the safety of each display during transit and it reduces the levels of waste likely to be immediately disposed of.

Philips professional displays are packaged in brown board boxes, and we have reduced the amount of ink we use by 45%, using only one colour and soy-based ink.

Palletisation

The way we pack our products for transport also has a big impact. Our ongoing palletisation project has, to date, resulted in a 184 ton Tank to

Wheel (TTW) CO2 reduction from reduced container space needed for transportation, and a 107 ton reduction of wood consumption and natural resources used, as well as a reduction of products damaged in transit, which in turn lowers WEEE.

Distribution

With factories in China, Poland, India, Mexico, Argentina and Brazil, we are ensuring a more even spread of production, also lowering logistics requirements.

We continue to monitor and refine in this area to ensure we minimise our impacts when it comes to transporting our products from our factories to our distribution hubs and end locations.